PROFILES IN EXCELLENCE

with Larry Langhurst and Bernie Becker of Woodesign

When Woodesign owners Larry Langhurst and Bernie Becker combined their talents, skill, and expertise in 1979, they began delivering signature woodworking that blended magnificent craftsmanship with superior service while infusing the principles of sustainability.

Now more than 35 years later, Woodesign is leading the charge together with DSC to raise the bar on green building so it is not just an outstanding achievement, but the standard. Join Team DSC® as we journey with Woodesign through the evolution of sustainable craftsmanship.

“I know I can speak for both Bernie and myself when I say our hearts and souls are into the philosophy of sustainability. While we don’t get to always do everything we want to make a project 100% sustainable, at least we’re trying to get people to think more towards that end. Hopefully we can plant the seed so that next time around we’ll get the chance to do everything we can to help the planet. My hope and my dream is that as we move further into the future, technology, and techniques enable homes to naturally become more efficient and more sustainable.”

“I know I can speak for both Bernie and myself when I say our hearts and souls are into the philosophy of sustainability. While we don’t get to always do everything we want to make a project 100% sustainable, at least we’re trying to get people to think more towards that end. Hopefully we can plant the seed so that next time around we’ll get the chance to do everything we can to help the planet. My hope and my dream is that as we move further into the future, technology, and techniques enable homes to naturally become more efficient and more sustainable.”

~ Larry Langhurst

Co-Owner, Woodesign

PLANTING SEEDS OF SUSTAINABILITY

IN THE BEGINNING

Larry Langhurst: When I first met Bernie, I had just come out of ASU and designed a whole line of furniture around the large wooden spools that Salt River Project put their wire on. I got them for a dollar a piece and learned how to take them apart and use everything out of them. I experimented with carpentry and bought accessories like screws and construction adhesive to practice joining the wood. All of my family’s furniture at the time was made from those spools, and we began selling them at flea markets. Besides building obvious things like round tables and bars, I also built a fence around the backyard out of them. Then I built swinging chairs, and all kinds of stuff like desks, couches, and benches – pretty much everything you could think of.

Based on this same philosophy of utilizing every part of the material we’re given, Bernie and I started officially incorporating sustainability into the Woodesign process in the early 90s. In those days, we used natural hide glues, whereas now we have more sophisticated ecological techniques such as presses that are heated and pressurized as well as two-part and protein-based glues that are really strong. All in all, we have always been extremely cognizant of our waste stream. It was a philosophy we have always had in our heads. To this day, we simply don’t want to be wasteful.

Bernie Becker: If there is anything left over like the smaller wood pieces that we can no longer use, we give those items away to our partners so they can use the wood scraps. They create desk accessories or cutting boards. We have a penholder on our desk that one of the architects brought back. He made it with his own hands from wood that was left from one of our bigger projects. It’s just one of the small ways we try to be sustainable along with our bamboo products and the veneers that we use from certified sustainable forests.

Bernie Becker: If there is anything left over like the smaller wood pieces that we can no longer use, we give those items away to our partners so they can use the wood scraps. They create desk accessories or cutting boards. We have a penholder on our desk that one of the architects brought back. He made it with his own hands from wood that was left from one of our bigger projects. It’s just one of the small ways we try to be sustainable along with our bamboo products and the veneers that we use from certified sustainable forests.

LIGHTING THE WAY

LIGHTING THE WAY

Bernie Becker: Specializing in veneers first caught my attention when we were hired to help build some large design pieces out of ash wood. We decided to bring in a log of veneers that ended up going a long way. I got to thinking that if we hadn’t used veneers, we would’ve had to order an entire railroad car full of solid wood. Veneers really make a difference in terms of sustainability because you’re just using part of one tree rather than cutting down a whole forest of trees for one project.

Larry Langhurst: On our website is a catalogue that describes our veneer process. Instead of cutting a log into one-inch boards, you’re shaving it into thin layers. The layers, or veneers, are sliced off of the log and then assembled. The core material that we put the veneers on is basically reprocessed wood chips. In effect, veneering is highly sustainable because you’re obtaining the greatest utility from a limited natural resource. With veneers, you’re going to get thousands of square footage out of a log as opposed to just one or two hundred.

Larry Langhurst: On our website is a catalogue that describes our veneer process. Instead of cutting a log into one-inch boards, you’re shaving it into thin layers. The layers, or veneers, are sliced off of the log and then assembled. The core material that we put the veneers on is basically reprocessed wood chips. In effect, veneering is highly sustainable because you’re obtaining the greatest utility from a limited natural resource. With veneers, you’re going to get thousands of square footage out of a log as opposed to just one or two hundred.

Bernie Becker: When we introduce the idea of using sustainable products and techniques, our clients usually react very positively. For example, when we tell a client their drawers are going to be made of sustainable bamboo and it’s renewable, their eyes light up. They feel like they’re part of saving the forest and the planet.

Bamboo is a great material. People often mistake it for wood, but it’s actually a grass that in some areas can grow up to two feet a day. Manufacturers take all that material and process it to be made into a variety of common products, from flooring and sheet goods to butcher blocks and large conference tables. In addition to drawers, we’ve crafted quite a few conference tables and desks out of bamboo and people love it. Now bamboo is available in different colors that help give our pieces real character.

Bamboo is a great material. People often mistake it for wood, but it’s actually a grass that in some areas can grow up to two feet a day. Manufacturers take all that material and process it to be made into a variety of common products, from flooring and sheet goods to butcher blocks and large conference tables. In addition to drawers, we’ve crafted quite a few conference tables and desks out of bamboo and people love it. Now bamboo is available in different colors that help give our pieces real character.

ADVANCING EL CHORRO LODGE

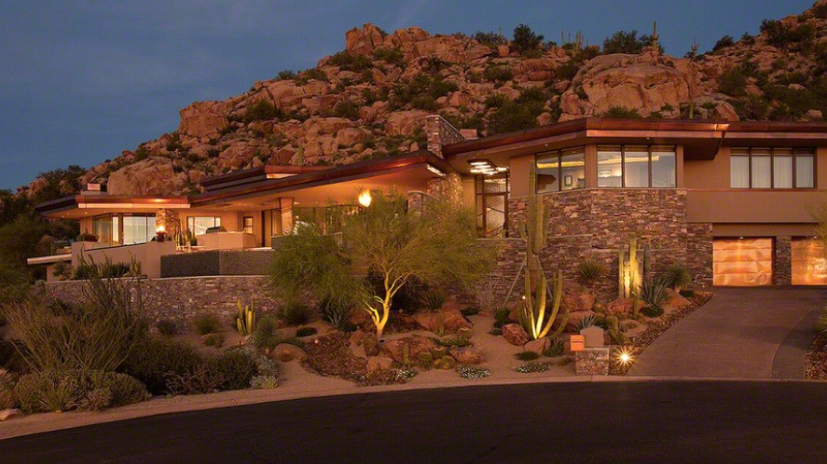

Larry Langhurst: Though Bernie and I have been in business together since 1979 and we’ve always known of DSC, we only recently started working on their sustainability projects. Our most recent project was El Chorro Lodge, but we came into the project five years after DSC completed their renovation.

About 10 or 15 years ago, I got ahold of 27 giant tables made from African Rhodesian Teak Wood. They had these big trestle bases, and I knew they would be perfect for restaurants. We still had those tables by the time the General Managers of El Chorro came around and hired us. The bar top that went from the inside to the outside of the main building was made of limestone. The finished design was great, but because the material held the heat from the sun, people were unable to lean on it once the stone became fiery hot. As a result, the managers decided they wanted to replace these stone bar tops with a wooden community table.

Thinking of the beautiful Teak Wood I still had in storage, I said to them, “I’ve got the lumber. It’s 125 years old and made from the old railroad ties from the African Rhodesian Railroad. It’s not going to get any more sustainable than this!” I always knew that these big thick trestles could be shaved up where we could get the maximum amount of use out of that wood. The design we came up with involved one of our longtime partners and friends Murray Herron from Accent Design & Manufacturing. He completed the steel work for us. The table is quite simple, running the boards together with the rails.

Jerry and Team DSC® knew we were replacing those original limestone tables, and we’re happy it’s such a good fit not only in terms of the traditional design of El Chorro, but also the sustainability aspect. When they originally did that remodel in 2010, I thought it was absolutely beautiful in terms of maintaining the original design philosophy while bringing the efficiency and sustainability into the 21st century. We look forward to doing more sustainability projects with Desert Star Construction.